Glass structures are becoming increasingly popular in modern architecture. But the use of ordinary raw glass for this purpose, in case of its destruction, exposes all people in the vicinity of the structures to danger. A modern and expedient solution in this situation is tempered glass or others (calendered glass, heat-strengthened glass, safety glass, tempered slope).

Tempered glass is ordinary raw glass, which has undergone a procedure of special temperature treatment in order to increase its mechanical strength. Structures made of tempered glass also have increased resistance to various temperature fluctuations. This is especially relevant in glazing of facades with reflector or tinted glass, which has a high coefficient of absorption of thermal energy and can be heated up to a temperature of 90-110 degrees Celsius. A big plus is the fact that tempered construction glass has stable optical characteristics throughout the entire life cycle. To date, glass tempering is one of the most important and popular types of processing. It is accepted to distinguish such varieties of tempered glass: transparent, energy-saving, patterned, reflective, frosted, milled, tinted.

The unique properties of tempered glass make its applications very diverse. The greatest popularity production of tempered glass is in the construction industry. For example, glass office partitions made of safety glass look modern and guarantee complete safety for others. The great popularity of tempered glass received in the manufacture of glass showcases in shopping centers. Very often in these constructions is used tempered glass 10 mm and 12 mm. Glass floor and glass staircases are the embodiment of fine taste and luxury, and always carry a huge design potential. Tempered glass is also popular in the manufacture of safety door structures, winter gardens, glass fences.

Manufacturing of tempered glass in Kiev

The production of tempered glass is similar to the hardening of steel. Tempered glass with a thickness of 10 mm or more is produced in special furnaces. Immediately after cooling, very high internal stresses appear in the upper layers of the glass, which give the glass great strength and resistance to temperature fluctuations.

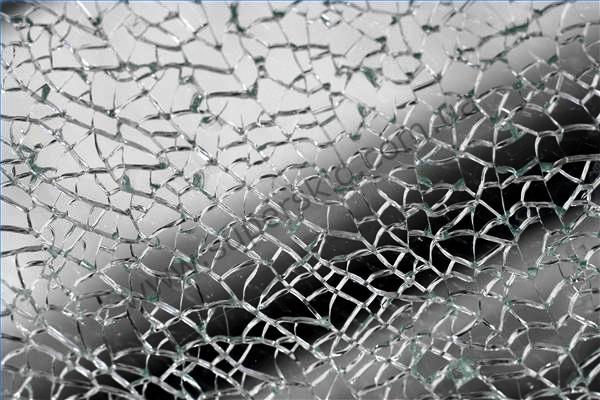

If we compare hardened glass with simple raw glass, the tempered glass after tempering is able to withstand 5-7 times stronger mechanical loads, as well as not destroyed by temperature shock. Of course, and tempered glass can be destroyed, but it crumbles into small pieces with blunt edges, 1 centimeter in diameter.

It is important to remember – tempered glass does not tolerate further mechanical processing, so cutting, grinding and polishing are performed before the procedure of tempering glass.

Compare the strength of raw glass, tempered glass, and steel.

| Material | Tensile strength at | Shock resistance | ||

| compression | stretching | bend | ||

| Steel | 200 MPa | 200 MPa | 200 MPa | 20 MPa |

| Regular glass | 1500 MPa | 50 MPa | 20 MPa

| 6 Pa. |

| Tempered glass | 1100 MPa | 300 MPa | 200 MPa | 30 MPa |

SUPERSKLO company together with Seven Glass offers services in glass tempering, glass bending. Automated lines allow hardening, bending of any type of glass, thickness from 4 mm to 19 mm. The most modern automatic 2 convection furnace for glass tempering provides both upper and lower convection.

Characteristics of tempered glass:

– any type of glass

– low-emission glass

– soft coated glass

– hard coated glass

– hard coated glass

– thickness of glass from 4 mm to 20 mm

– minimum sheet size: 150 mm x 350 mm

– maximum sheet size: 2440 mm x 4200 mm

Benefits of heat-strengthened glass:

– increase in impact strength of glass in 7-10 times

– increase in flexural strength 250 MPa

– wide temperature range of glass operation

– resistant to temperature shock

Calcareous glass applications :

– facade glazing

– skylights, glass domes

– translucent structures, storefronts

– glass partitions to the bathroom from tempered safety glass

– attics, stairs, glass partitions, winter gardens

– in the production of glass furniture and interior solutions

Radius glass. Glass milling.

Glass bending services milling a method of glass forming based on the ability of heated glass mass to deform under the influence of special presses. This process resembles glass tempering, but the glass after leaving the furnace enters the tempering section, where the flat glass is bent by rollers or.

The equipment allows to produce glass bending from different types of glass:

– bent clear glass

– curved tinted glass

– bent sunscreen glass

– bent decorative glass

Technical capabilities for glass bending:

- Thickness of molten glass 4 -16 mm

- Minimum glass size 300 x 200 mm

- Maximum glass size 1800 x 2440 mm

- Glass bending radius 600 mm -1500 mm

- Bending arc length from 300 to 600 mm

| Minimum glass bending radius | ||

| Glass thickness, mm | Arc length, mm | R |

| 4, 5, 6 | Arc length ≥600 mm | 800 mm |

| 4, 5, 6 | 300 mm ≤ Arc length ≥ 600 mm | 900 mm |

| 8, 10 | Arc length ≥600 mm | 900 mm |

| 8, 10 | 300 mm ≤ Arc length ≥ 600 mm | 1200 mm |

| 12, 15 | Arc length ≥600 mm | 1200 mm |

| 12, 15 | 300 mm ≤ Arc length ≥ 600 mm | 1200 mm |

Cost of Tempered Glass in Kiev

| glass thickness | deaf/otv | deaf/otv | deaf/otv |

| from 5 m/sq. ft. | from 100 m/sq. ft. | from 1000 m/sq. | |

| 4 | 750/850 | 650/750 | 510/610 |

| 5 | 880/950 | 690/790 | 620/730 |

| 6 | 970/1050 | 790/890 | 700/810 |

| 8 | 1480/1650 | 1400/1550 | 1340/1450 |

| 10 | 1680/1780 | 1580/1680 | 1480/1580 |

| 12 | 2350/2450 | 2250/2350 | 2150/2250 |

| 19 |

Cost of Super Transparent Tempered Glass

| glass thickness | deaf/otv | deaf/otv | deaf/otv |

| from 5 m/sq. ft. | from 100 m/sq. ft. | from 1000 m/sq. | |

| 4 | 870/980 | 770/850 | 680/780 |

| 5 | 1080/1180 | 980/1080 | 880/980 |

| 6 | 1360/1460 | 1260/1360 | 1160/1260 |

| 8 | 1760/1960 | 1660/1860 | 1560/1760 |

| 10 | 2150/2350 | 2050/2250 | 1930/2150 |

| 12 | |||

| 19 |

Cost of tinted (bronze, graphite) Tempered glass

| glass thickness | deaf/otv | deaf/otv | deaf/otv |

| from 5 m/sq. ft. | from 100 m/sq. ft. | from 1000 m/sq. | |

| 4 | 790/950 | 690/850 | 600/730 |

| 5 | 950/1100 | 850/950 | 750/850 |

| 6 | 1260/1380 | 1060/1180 | 960/1080 |

| 8 | 1650/1880 | 1550/1790 | 1490/1610 |

| 10 | 2050/2180 | 1950/2080 | 1850/1980 |

| 12 | |||

| 19 |

Glass and mirror frosting

| Name of the work | Price, UAH/m² – wholesale (1000 m2) |

| Solid matting + hydrophobic | 130грн/м.кв. |

| Artistic matting + hydrophobic | 265грн/m.кв. |

| Artistic embossing of amalgam | 450 UAH/sq.m. |

| Deep artistic matting | 1500 UAH/sq.m. |

| Triplexing | 800 UAH/sq.m. |

| Triplexing with a matte film | 1100 UAH/sq.m. |

Please note, our company can perform a complex delivery of tempered glass, fittings and perform installation of any glass products including such as:

– Glass partitions in the bathroom Shower Loft Partitions